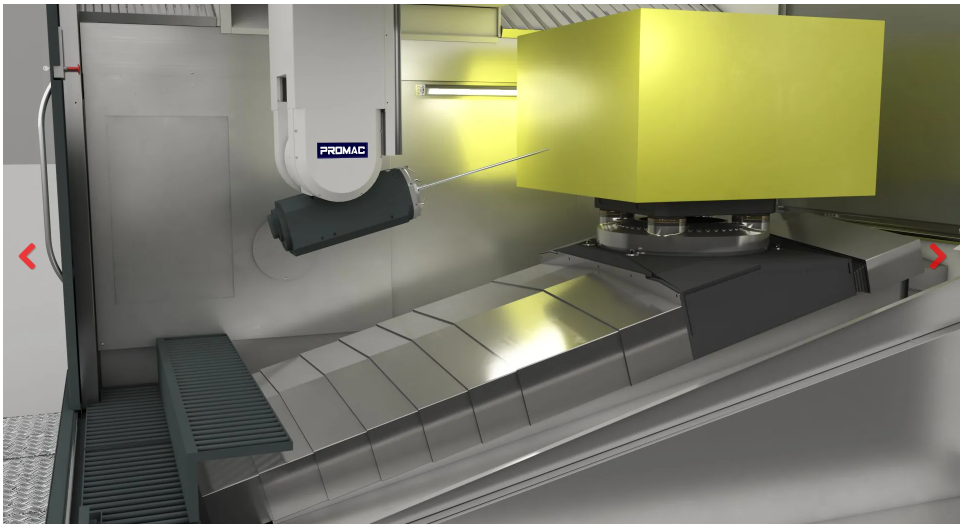

MACHINING CENTER

Machining Center for Boring, Milling and Turning

Speedmat VM technology provides the perfect solution for the most demanding machining applications requiring utmost rigidity and precision even on the hardest materials. Multitasking capability allows for milling, boring and turning operations to be carried out in the same set up.

Speedmat VM multitasking CNC machining centers may be customized to cater for the needs of the most demanding applications in fields of applications such as:

- aerospace

- energy

- earth moving

- die & mold

- general machining

- for boring, milling and turning

- pallet size from 39 x 39 in up to 79 x 79 in

- maximum work piece swing diameter from 59 to 118 in

- maximum table load capacity from 13200 to 26400 lbs

The Speedmat VM series consists of three base models with: pallet size from 39 x 39 in up to 79 x 79 in with maximum table load capacity from 13200 to 26400 lbs and maximum work piece swing diameter from 59 to 118 in.

FLOOR TYPE BORING AND MILLING MACHINE

Large Size CNC Boring and Milling Machines

The hydrostatic boring and milling machine Speedram is designed for high precision, power and structural rigidity, providing the perfect machining solution for the most demanding applications on all heavy, medium to large size components, requiring high material removal rate coupled to high precision and superior finishing even in hard-to-cut materials. Speedram CNC boring and milling machines can be equipped with several type of tool magazines and automatic attachment changers and customized accessories (such as universal heads, 2 axes contouring heads, right angle heads, universal heads with orthogonal axes and facing heads) to cater for the needs of the most demanding applications in fields of applications such as:

- energy

- oil & gas

- shipbuilding

- earth moving

- general machining

- boring spindle diameter 5.1 – 10.2 in

- vertical stroke from 79 – 394 in

The hydrostatic floor type boring and milling machines Speedram are available in six basic models with boring spindle diameter from 5.1 to 10.2 in, spindle power from 50 to 195 HP and vertical strokes from 79 to 394 in. The boring and milling machine Speedram can be equipped with a wide range of hydrostatic rototraversing tables with loading capacity from 110000 to 1323000 lbs.

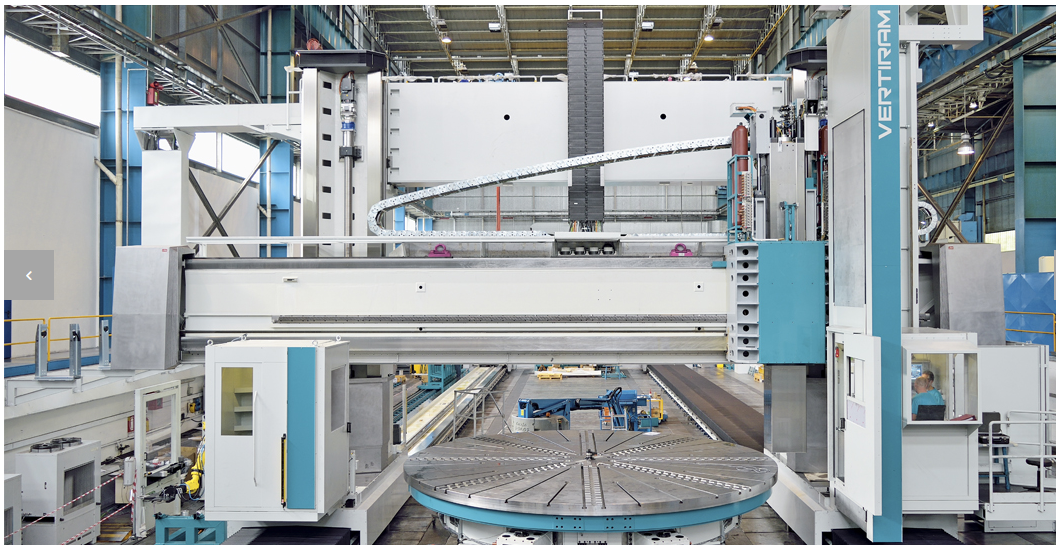

GANTRY TYPE MACHINING CENTER

Vertical CNC Machining Centers

The vertical gantry type machining center Vertiram is designed to be the perfect solution for large or heavy components whose machining is best performed in the vertical spindle plane. An unlimited number of boring, milling and turning operations can be performed in single set-up configuration. The Vertiram range of portal machining centers is available in movable gantry type (GT) and movable table type (TT) models, both of which can be provided with fixed or movable crossrail and turning table options, turning into a boring, milling and turning center for multitasking operations.

Vertiram CNC machining centers may be customized with a wide range of turning tables with loading capacity from 6600 to 661000 lbs, a wide range of head attachments (such as universal heads and five axes CNC heads and heads for customized solutions), tool magazines and other accessories to cater for the needs of the most demanding applications in fields of application such as:

- aerospace

- die & mold

- earth moving

- diesel engines

- energy

- movable gantry type machining centers (GT)

- movable table type machining centers (TT)

Wide range of clearance between the columns, from 83 to 398 in, clearance under spindle from 67 to 217 in and ram Z-axis stroke from 51 to 98 in.